We saw multiple efforts and initiatives taken up by companies across the globe to tackle the Covid-19 pandemic. We continue our effort to showcase similar efforts taken by other companies and how they are helping doctors, healthcare workers and patients amid the Coronavirus outbreak.

GLOBAL AUTOMAKERS JOIN THE FIGHT AGAINST COVID-19 WITH 3D PRINTING TECHNOLOGY

Carmakers from across the world are joining the efforts to fight Covid-19 by using 3D printing technology at their disposal. From among them, German automaker Volkswagen has assembled a task force and will be using its 125 3D printers at its disposal to make hospital ventilators.

Other automakers like Ferrari, Ford, Nissan and General Motors have also pledged their support to ramp up the production of ventilators and other equipment to treat the fast-spreading disease.

According to a recent statement released by Volkswagen it revealed that it was testing materials and checking supply chains to see how it can use 3D printing to help manufacture hospital ventilators and other life-saving equipment.

The statement also stated, “Medical equipment is a new field for us. But as soon as we understand the requirements, and receive a blueprint, we can get started. Prototype components have been printed and its Skoda arm is included in the project.”

U.S. automaker General Motors disclosed that it is working with Ventec Life Systems, a medical device company, to enable rapid production of ventilators and also to leverage GM’s logistics network.

GM CEO Mary Barra explained, “We are working closely with Ventec to rapidly scale up production of their critically important respiratory products to support our country’s fight against the COVID-19 pandemic.”

Munich-based carmaker BMW too revealed that it was ready to help with the production of components using 3D printing technology.

In a similar news apart from 3D printing, Chief Executive of Porsche Oliver Blume expressed his support to the relief efforts.

ISINNOVA CONVERTS SNORKELING MASK INTO A NON-INVASIVE VENTILATOR WITH A 3D PRINTED ADAPTER

Isinnova, an Italian 3D printing start-up, collaborated with Decathlon, the French sporting goods retailer, to convert its snorkelling masks into a non-invasive ventilator with a 3D printed adapter.

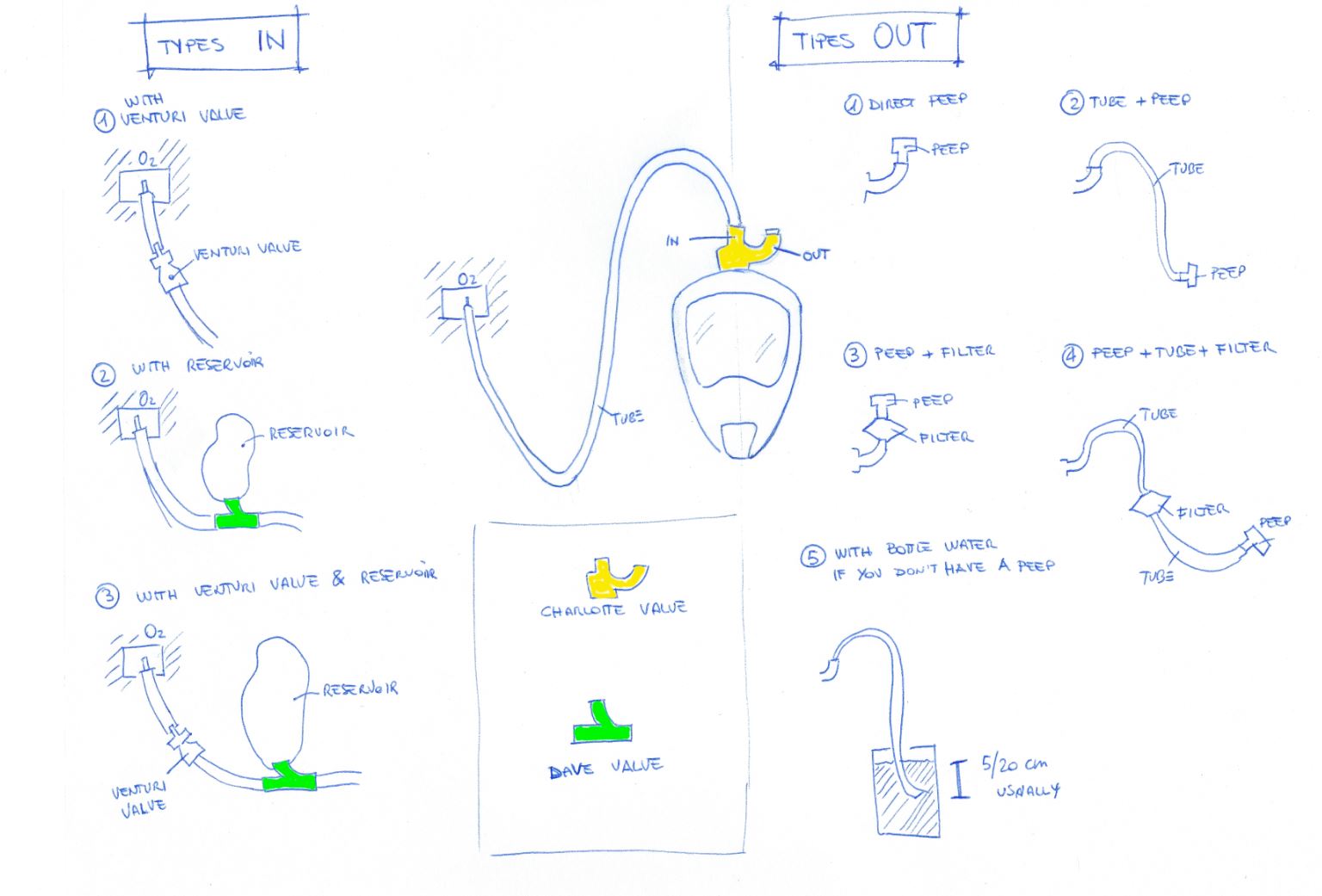

The actual product in use was dismantled and studied so that a new component could be used to connect the mask to the ventilator. This new part is now named Charlotte valve, and it can be rapidly produced using Stereolithography (SLA) 3D printing technology.

Above: Video on how to use the Charlotte Valve/Video Credit: Isinnova/Cristian Fracassi

But the main task was to get an approval from the doctors and so the prototype was tested at Chiari Hospital. The part connected to the ventilator body, proved to be working. The device was then tested on a patient and it passed this second test as well. However, the inventors emphasize that neither the mask nor the link is certified and their use is recommended only in an emergency situation and should be used only with the patients’ acceptance.

Isinnova also went ahead and patented the link valve (Charlotte Valve) on priority. It said, “The patent will remain free to use because it is in our intention that all hospitals in need could use it if necessary. Our initiative is totally non-profit, we will not obtain any royalties on the idea of the link, nor on the sales of Decathlon masks.”

You can freely download the file for printing the same. The page also has a selection of other useful 3D printable files for both healthcare institutions and the general public.

Recently, Isinnova had also 3D printed respiratory valves for breathing machines, to perfectly carry out the function of the valves.

HP MOBILISES 3D PRINTING TEAM TO PROVIDE ESSENTIAL CORONAVIRUS MEDICAL GEAR

HP, the technology giant, announced in an official statement that it is mobilizing its 3D printing team and HP’s Digital Manufacturing Partner Network to design, validate and produce essential parts for medical responders and hospitals.

The network may manufacture parts such as ventilator valves, breathing filters and face mask clasps, as well as entirely new parts such as plastic door handle adaptors which enable easy elbow opening to prevent further spread of the virus.

It revealed, “We will make available any HP proprietary design files for these parts so they can be produced anywhere in the world and are also helping end-customers bridge potential supply chain interruptions by expanding distributed print-on-demand capabilities.”

HP revealed that it is also deploying its BioPrinters and associated supply cassettes, free of charge, to NGOs, government agencies and pharmaceutical companies to accelerate drug and vaccine research to combat COVID-19.

Additionally, the company is also donating millions of dollars in technology and support through a concerted effort across Personal Systems and Print to help students, families and communities.

STRATASYS TO RAMP UP PRODUCTION OF 3D-PRINTED PERSONAL PROTECTION EQUIPMENT

Stratasys Ltd. announced that it will be using its expertise in GrabCAD, Stratasys Direct Manufacturing and partner network with donated printing capacity across all regions in response to the COVID-19 pandemic. Its initial focus is on providing thousands of disposable face shields for use by medical personnel.

In the United States, Stratasys has set an initial goal of producing 5,000 face shields by Friday, March 27, at no cost to the recipients. This includes both a 3D printed frame and a clear plastic shield that covers the entire face. The company will have the ability to scale to an even faster rate of production.

One of the world’s top hospitals has told Stratasys they use 1,530 disposable face shields every week even without the surge created by COVID-19 and is down to six days’ inventory on hand, with the pandemic still building momentum.

Stratasys has set up a web page where organizations can request 3D printed products to help with the crisis, offer 3D printing capacity, or request 3D printers or material for medical- or safety-related purposes. Visit www.stratasys.com/covid-19.

LEITAT PRESENTS FIRST MEDICALLY VALIDATED, INDUSTRIALIZED 3D PRINTED VENTILATOR

A six-member alliance of partners like the Consorci de la Zona Franca (CZFB), HP, Leitat (Tecnio) together with CatSalut, through the Consorci Sanitari de Terrassa (CST) and the Hospital Parc Taulí de Sabadell, resulted in the development of the first industrialized field 3D printed emergency respiration device (strictly to be used only in an emergency situation) to support hospitals and ICUs. The device is a mechanical bag valve mask (BVM) that can be used for short term emergency ventilation of COVID-19 patients.

The 3D printed respirator is designed and developed by the Leitat Technology Centre in urgent response to the severe shortage of medical supplies used to treat Covid-19 patients.

On account of the rapid rise in the number of patients and resulting shortage of supplies, hospitals in Italy are refusing to admit patients older than 65 years of age. The 3D printed respirator fits perfectly in this scenario.

A lot of initiatives are being started by the 3D printing community but a lot of products coming out of those initiatives are yet to be medically approved. In this respect, the Spanish initiative has been successful in producing a medically approved device that could be produced on a large scale.

The team is already working on a second model the Leitat 2, which should be more in line with the regulations of the Spanish Agency for Medicines and Medical Devices.

CONCLUSION

The world is facing a crisis like no other in recent history and it needs to unite against the same. The 3D printing industry is using all its capabilities of rapidly producing new or replacement parts and showcasing the power of the technology and playing its part in the fight against Covid-19.

(Note: Manufactur3D is not responsible for the legality, validity and feasibility of the products mentioned in this article but we are reporting on how companies have taken up numerous initiatives to fight against the pandemic. We are not responsible for the effects of the products – good or bad)

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Global News page for more updates on Global 3D Printing News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn.